Client

Location

Services Provided

- Pipe video inspection

- Pipe pressure testing

- Alternatives evaluation

- Outlet works design

- Water control gates and valves

- Construction documents

- Underwater construction

- Resident engineering

- Construction administration services

Challenges

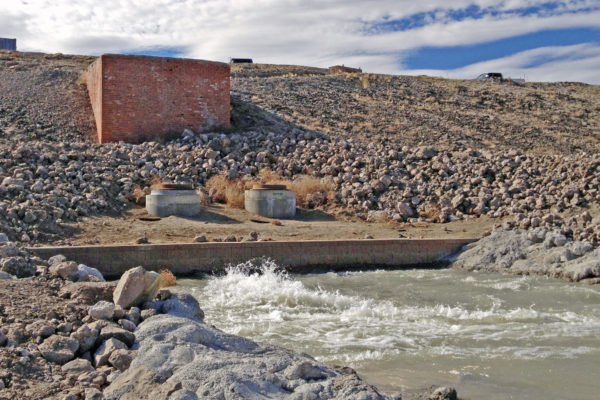

St. Charles No. 2 Reservoir was originally constructed in 1900 to supply industrial water for a steel mill near Pueblo, Colorado. The original outlet works consisted of two 24-inch-diameter cast iron pipes with control valves in the dam’s midsection. The valves had not been operated in over 10 years. An underwater inspection oversaw by RJH revealed the intake structures had become covered by more than 10 feet of silt and neither outlet valve could be opened.

The reservoir is held at constant elevation for steel operations and is not allowed to vary by more than 0.5 vertical foot. Reservoir withdrawals for steel operations occur through a separate pipeline. The steel mill required construction to be performed without lowering the lake elevation or disrupting water flow to the mill. Loss of water to the steel mill would stop all production operations and cost the owner approximately $250,000 in revenue per hour.

Solution

RJH performed conceptual through final designs, and provided construction phase services for the project. Early in the design process, RJH worked closely with an underwater construction contractor to evaluate the challenges and create a rehabilitation approach to facilitate underwater construction without impacting steel operations.

The construction sequence began with dredging the intake structures and cast-iron pipes, which were full of sediment, and pressure testing the pipes. The pipes were determined to have integrity issues and required rehabilitation. The existing intake structures were demolished and replaced with new pre-cast structures. The existing pipes were lined with an HDPE liner and the annulus was grouted with a specially formulated grout mix.

The final stages of construction involved installing a precast concrete intake structure with hydraulically controlled slide gates at the midsection of the dam and constructing a filter diaphragm, discharge structure, and stilling basin. RJH worked closely with the selected specialty underwater contractor throughout the construction process to successfully overcome continuing challenges presented by constructing this complex project under full reservoir head.